High vertical manufacturing range

At the Wuppertal factory, more than 30 plastic injection moulding machines with a mould closing force of up to 100 t are running around the clock. The central material supply and the automated handling tools provide for an “unattended” operation. The injection moulds are manufactured by our own Tool Engineering and Design Department. The electronics is also in-house manufactured on several production lines equipped with SMD pick & place machines, printers and solder waves. All electronic modules are subject to comprehensive tests prior to their assembly.

In the machine shop, we prepare the enclosures and other components for our switchgear. In addition to the conventional machining work, modern CNC machining centres are used as well.

The electronics are manufactured in the Wuppertal and Wettenberg production plants on several production lines equipped with soldering paste printers, SMD pick & place machines, furnaces and solder waves. All electronic modules are subject to comprehensive tests prior to their assembly. We thereby use a combination of manual and automated optical inspection (AOI) procedures as well as device-specific functional tests.

Assembly and check

As we manufacture a wide range of variants for almost all of our products, the majority of our devices are completely assembled by one person on individual workstations. For product series, which are produced in very large batches, automated assembly cells and lines are used.

All final assembly stations are equipped with test equipment saving the test results into a central database. In this way, any divergence from the reference values can be quickly detected so that possible countermeasures can be initiated. The test equipment has been designed, developed and built by our own department.

Committed to sustainability

With product lifetimes of sometimes more than thirty years and the corresponding long obligation to spare parts supply, we have to meet the challenge of pursuing both a flexible and a sustainable production strategy. This requirement is met by consequent standardisation and accurate documentation.

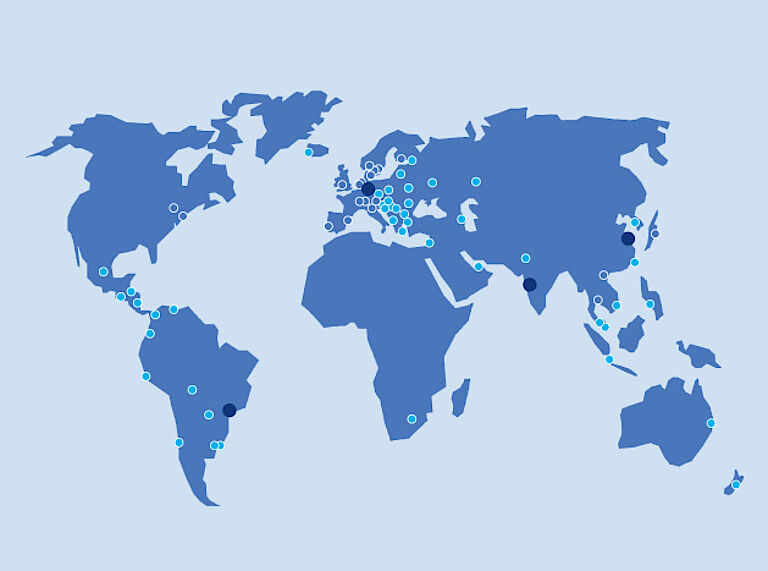

International collaboration

Currently, the Schmersal Group has seven production plants on three continents. The latest addition at the beginning of 2014 was the new plant in Ranjangaon, India and has been integrated into the production network. The principle is to meet the needs of the local markets with local production and to ensure a globally uniform quality of the production program. Here, the Wuppertal “Lead Factory” takes care for the constant optimisation of the processes in close collaboration with the other sites. In this way, we want to meet the requirements of the local markets by an on-site production on the one hand and guarantee a worldwide uniform quality of our product programme on the other hand. This is realised by using a uniform machinery park in the European, American and Asian plants.